Best Practices in Curriculum Design for Vocational Training

Chosen theme: Best Practices in Curriculum Design for Vocational Training. From welding bays to healthcare labs, we translate real work into purposeful learning. Dive in, borrow our best ideas, and tell us what works in your classrooms, workshops, and apprenticeships. Subscribe to keep practical insights flowing.

Start With Job Tasks, Not Textbooks

Interview supervisors, observe workflows, and list the critical tasks workers must perform safely and consistently. A collision repair instructor once filled a whiteboard with steps from an actual shop job card, then turned each step into a teachable moment.

Co-Create Standards With Employers

Invite a small advisory panel to validate competencies and prioritize must-have skills. Use their language. One college brought line supervisors to a lab walkthrough, and the checklist they scribbled became the heart of an updated course outline.

Keep Competencies Measurable and Observable

Write outcomes that specify conditions, tools, and performance criteria. Replace vague statements with observable behavior. Instead of understands electrical safety, use isolates power and verifies zero energy using lockout procedures in under five minutes.

Modular, Stackable Learning Pathways

Give every module a crisp goal, an authentic assessment, and an artifact of learning. Learners should leave with a concrete product, from a precision-machined part to a coded PLC routine they can proudly showcase.

Modular, Stackable Learning Pathways

Align modules so achievements build naturally toward higher-level credentials. A student who earns a safety microbadge in carpentry should carry it into construction management, reducing redundancy and speeding their progress toward employment.

Modular, Stackable Learning Pathways

Use challenge tasks, performance verifications, and reflective interviews to credit experience. A veteran field technician proved compressor diagnostics competence in ninety minutes, then used freed time to deepen customer communication skills.

Set expectations for supervision, exposure to core tasks, and feedback cadence. One bakery partnership promised two supervised dough setups per week, ensuring every apprentice practiced time-sensitive processes under authentic production pressure.

Assessment That Mirrors the Workplace

Build Performance Tasks With Clear Rubrics

Create checklists for accuracy, speed, safety, and professionalism. In HVAC lab assessments, learners diagnose a faulted system, explain their reasoning, document readings, and restore operation while maintaining customer-ready communication.

Use Portfolios To Show Evidence Over Time

Collect photos, reports, checklists, and supervisor notes. One welding student kept a progression of beads, with heat settings and reflections, revealing steady improvement from inconsistent travel speed to clean consistent puddle control.

Make Safety and Compliance Non-Negotiable

Gate progress with verified safety skills. Before touching a live panel, every learner must pass lockout tagout and demonstrate correct PPE use. Confidence in safety frees learners to focus on troubleshooting depth.

Inclusive Design and Universal Access

Pair diagrams, brief videos, and hands-on models with plain language guides. Let learners show competence through live performance, annotated photos, or short recorded walkthroughs, keeping assessment rigorous and genuinely accessible.

Instructor Growth and Continuous Improvement

Run Small Plan Do Study Act Cycles

Pilot a revised task sheet for two weeks, collect learner artifacts, and compare outcomes to last term. Celebrate gains, fix bottlenecks, and document the change so improvements become standard practice.

Use Learning Analytics Thoughtfully

Track attempts, errors, and time on task to spot where learners stall. An automotive program noticed repeated trouble at sensor calibration and added a short targeted clinic that halved rework.

Build Communities of Practice

Host brief show-and-tell sessions where instructors swap rubrics, labs, and lesson hooks. A robotics team shared a quick jig for cable management that saved setup time across three different programs.

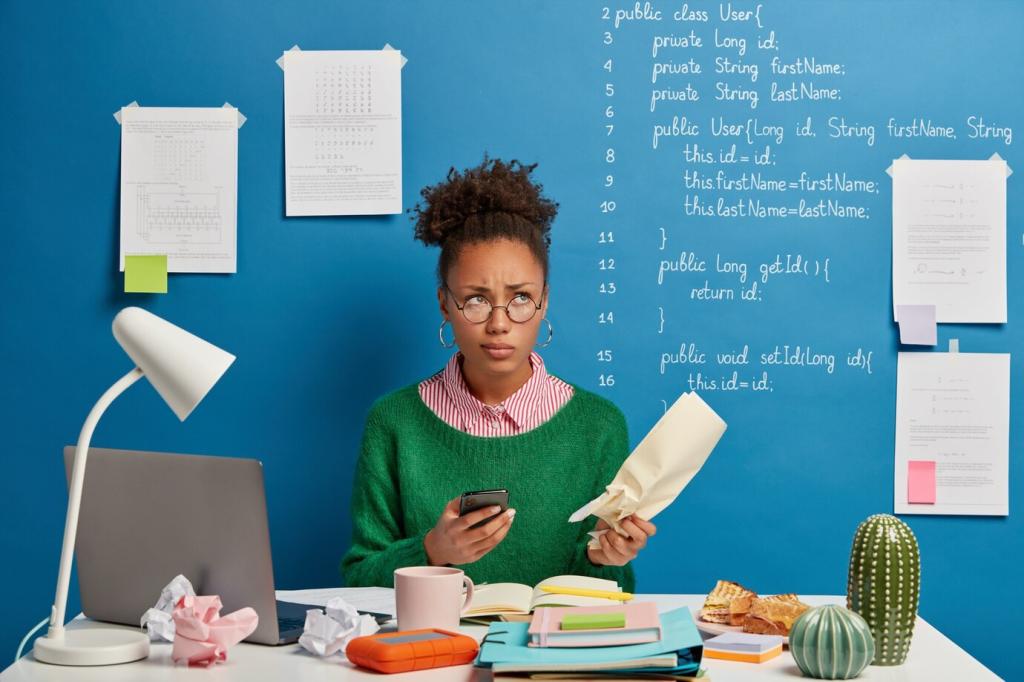

Technology and Tools Aligned to Industry

Adopt the Tools Employers Expect

When possible, teach on the same software, meters, or devices used on the job. Graduates who practiced on current diagnostic platforms needed less onboarding and often mentored peers within weeks.

Leverage Simulators for Safe Repetition

Use AR, VR, or desktop simulators to rehearse rare or risky scenarios. Forklift learners practiced tight turns virtually, reducing first-week accidents and boosting their confidence before stepping into the warehouse.

Keep Content Current and Open

Maintain living lab guides and short update briefs for new standards or equipment. Encourage feedback in shared documents so instructors and students co-author improvements that keep learning materials fresh.

Join our mailing list